Core Products

菜单

- Intelligent Inspection Robot on ...

- Intelligent Inspection Robot on ...

- EMU online mobile rim spoke ultr...

- Locomotive online mobile rim spo...

- Double track ultrasonic flaw det...

- Intelligent Permanent Way Disast...

- Data Repair System...

- Power supply system BIM platform...

- Multi-channel big data wireless ...

- Dispatch Emergency Command Syste...

- EMU Bogie Maintenance Line Syste...

- EMU Online Mobile Wheel Rim & Wh...

- Fixed Hollow Shaft Ultrasonic De...

- Mobile Hollow Shaft Ultrasonic D...

- EMU Oil Monitoring System...

- EMU Bogie Dynamic Load Test Stan...

- EMU Bogie Static Load Test Stand...

- System Integration of EMU Wheel ...

- Wheel Set Dimension Measuring Ma...

- Maglev train maintenance system ...

- Rolling Stock Wash Plant...

- Wheel Malfunction Online Detecti...

- Rain Running Fault 3D Image Dete...

- On-Board Test System of Contact ...

- Test and Monitoring System of Co...

- Running Preparation Comprehensiv...

- EMU Shunting Safety Monitoring S...

- Computer Interlocking System...

- Overload / Unbalanced Load Detec...

- GFJX-100 Steel Rail Welding Join...

- GFJZ-50 Steel Rail Full Cross Se...

- GZH-70 Steel Rail Post Weld Heat...

- HGCY06-ⅡModel Rail Replacement ...

Test and Monitoring System of Contact Line Hanging (4C)

This device adopts advanced accurate position, high speed image acquisition, super uniform integrated light source, geometric parameter measurement, image automatic recognition technology to achieve the high speed capture, storage and analysis of the image of the pantograph suspension parts, it carries on full analysis of pantograph status such as loosing, dropping off and cracking as well as automatic detection and makes timely pre-warning and instructs the elimination of the fault to ensure safe operation of the contact line.

Products Characteristics

- Accurate Positioning Technology

It achieves the shooting error that is less than 20mm on same line same parts, offers important data foundation of the key parts abnormity automatic comparison recognition.

- Super Uniform Integrated Light Source Technology

It achieves the basically same gray value and ensures image abnormity analysis is not affected by the light source and the environment.

- Image Automatic Recognition Technology

It achieves the pole number image automatic recognition and key parts status abnormity automatic analysis comparison recognition and reminder. While the reminder can be divided into pre warning, report warning and warning to decrease the workload of the maintenance people, shorten the working time and improve the working efficiency.

- Contact Line Geometric Parameter Continuous Measurement

It could make accurate measurement on contact line height, gradient, altitude intercept, lateral deviation and lateral separation. By comparing with the history detected data realize timely pre warning, report warning and warning.

- Artificial Intelligence Technology

It collects and generates fault analysis report and fault case library based on line, depot and bureau to provide decision basis for detection and maintenance.

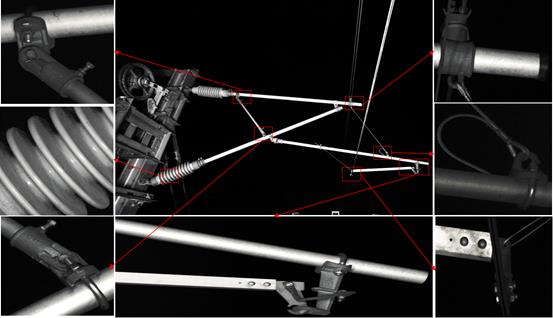

Picture 1 On Site Installation Equipment Picture

Picture 2 Ground Analysis Center

Picture 3 Train Inside Acquisition Software Operation Interface Picture

Picture 4 Contact Line Geometric Parameter Detecting System Real Time Processing Software Working Interface

Picture 5 HD Shooting Effective Picture

Automatic Recognition Case

神州高铁技术股份有限公司

神州高铁技术股份有限公司