Overall Solutions

Long Rail Welding Base’s Packaged Technology and Equipment Solutions

Wuhan LEADDO Measuring & Control Technology Co., Ltd has been committed to improve the welding process of accuracy, efficiency and equipment’s automatic degree, reliability, safety, etc. LEADDO follows the aim of “ the first-class of technology and equipment, the first-class of working environment, the first-class of staff quality, the first-class of enterprise management, the first-class of product quality” in the process of equipment innovation. After several years’ development, it has formed a packaged technology and equipment of long rail welding base for 500m seamless high-speed rails.

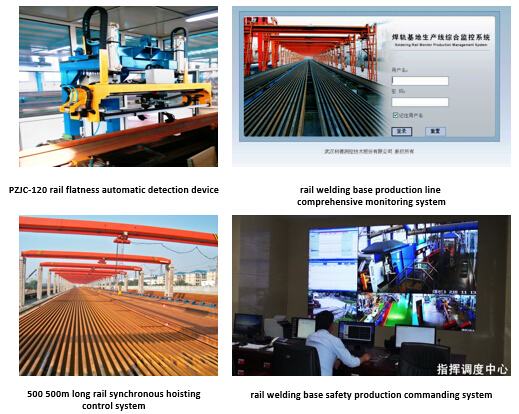

The solution covers rail welding base production line comprehensive monitoring system, 100 meter-gauge automatic rail loading device, rail welding derusting machine, rail welding dehumidification machines, rail welding full cross section milling machining center, rail flatness automatic detection device, rail welding CNC precision milling machine, 500-meter-long rail synchronous hoisting control system, which runs through the entire welding rail production line. It adopts the world’s initial processing craft, which uses ‘milling’ to replace the ‘grinding’, as well as the advanced Gray Bus positioning technology. With high degree of automatic equipment, most of the equipment can be completed all the work by a key operation.

Currently, LEADDO provides packaged equipment solutions for Wuhan, Shanghai, Xi’an, Taiyuan, Jinan, Lanzhou, Harbin, Zhengzhou and other rail welding bases.

Visualization design of Wuhan 500m long rail welding base’s packaged technology and equipment

Real map of Wuhan 500m long rail welding base’s packaged technology and equipment

神州高铁技术股份有限公司

神州高铁技术股份有限公司